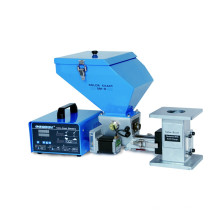

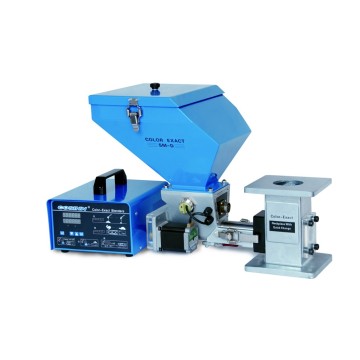

Color Dose Mixer Single Shaft

Basic Info

Model No.: CM3020

Product Description

Model NO.: CM3020

Application: Granules

Application Area: Daily Chemical

Additional Capabilities: Dosing

Condition: New

Transport Package: Tri-Ply Wooden Case

Mixer Type: V-Mixer

Certification: CE

Layout Type: Verticle

Operating type: Continuous Operating

Trademark: SIMI

Origin: China

CM SERIES Volumetric Doser

CM series volumetric dosers are suitable for auto-proportional mixing of virgin materials, regrinds, master-batch or additives. Brusheless DC motors are adopted. According to the proportion and data set up, its micro-computer control system turns into referred speed, drive the precise SS304 dosing screw by the coupling, throw out the required material into injection machine. Its error value is below 1%. Give a total of six models with output ranging from 0.1~100kgs /hr. Double color dosers can be assembled from two single color dosers if required. Five components automatic mixing can be realized if customers adopt four color dosers.

| MODEL | SINGLE | DOUBLE | |||||||

| CM3025 | CM3020 | CM3016 | CM5025 | CM5016 | CM-D30/30 | CM-D30/50 | CM-D50/50 | ||

| Motor(W) | 50 | 50 | 50 | 50 | 50 | 30×2 | 30×2 | 30×2 | |

| Speed(rpm) | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | |

| Mixing(W) | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | |

| Screw | 25 | 20 | 16 | 25 | 16 | * | * | * | |

| output(kg/h) | 1.1-38 | 0.6-20 | 0.3-10 | 0.5-17 | 0.1- 4 | ** | ** | ** | |

| hopper(L) | 10 | 10 | 10 | 10 | 10 | 12×2 | 12×2 | 12×2 | |

| ratio | 30 | 30 | 30 | 50 | 50 | 30 / 30 | 30 / 50 | 50 / 50 | |

| SIZE | |||||||||

| H mm | 520 | 520 | 520 | 520 | 520 | 615 | 615 | 615 | |

| W mm | 610 | 610 | 610 | 610 | 610 | 1045 | 1045 | 1045 | |

| D mm | 335 | 335 | 335 | 335 | 335 | 335 | 335 | 335 | |

| Net weight kg | 15 | 15 | 15 | 15 | 15 | 33 | 33 | 33 | |

(Output based on plastic of ratio 1.2kg/dm³,diameter 2-3mm working continuously for reference. )

Mixing Base is Optional Choice.

Features:

* Dosing screws are chrome plated for durability.

* Unit is comprised of standard modules for ease of cleaning, disassembly and interchangeability.

* Blender is a standard equipment for double color doser to make the material evenly mixed, while also a optional equipment for single color doser to do so.

* Main material hopper is a standard equipment for double color doser. It is optional for single color doser.

* External signals can be directly interfaced with control box.

* The current operation mode can be recorded, unaffected by power failure so operation would be returned to normal when power is on.

* Forced material cleaning is convenient to replace masterbatch.

* Applicable on extrusion machines, just need to make a few wire replacements.

* Rotating speed can be automatically adjusted according to extruder processing speed, which maintains the fixed proportion of masterbatch.

* 50 units of parameter recipes are available for permanently recording the period of material discharging and finished products weight (for extruder, it is max. Throughput per minute).

* Use brushless DC motor and free from maintenance.

* Both master blockage and overload can be detected, then machine will halt and sound alarm.

* Based on customers demand, some mold cycles can be set to add additives periodically so that micro-metering can be achieved.

Contact us if you need more details on Screw Doser. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Volumetric Doser、Screw. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Mixing & Separating Series

Premium Related Products

Other Products

Hot Products

Air Cooled Low Temperature Chiller for -35c to 0c Temperature RequirementLow Temperature Air Cooled Water Chiller for Medical MachineMsthb-100 Ton Closed Circuit Cooling TowerAir Cooled Chiller with Anticorrosive Water LoopAir Cooled Heating and Cooling Water Chiller UnitAir Cooled Screw Water Chiller for Plastic Machine8ton to 150ton Cooling TowerMold Temperature Controller(Oil and Water)1HP to 60HP Portable Air Cooled Industrial Water ChillerJFT Series Counter Flow Cooling Tower JFT-350ULCounter Flow & Squre Closed Cooling Tower (JFC Series)Round FRP Cooling Tower JLT-30L/ULCTI Certified Cross Flow Closed Type Cooling Tower (JNC-80T)Industrial Cooling Tower (JBNG-2500X4)Cross Flow Rectangular Cooling Tower (JN-100L/S)JNT Series Super Low Noise Cross Flow Rectangular Cooling Tower (JNT-150UL)